Installation Procedure: Brake Booster

01.

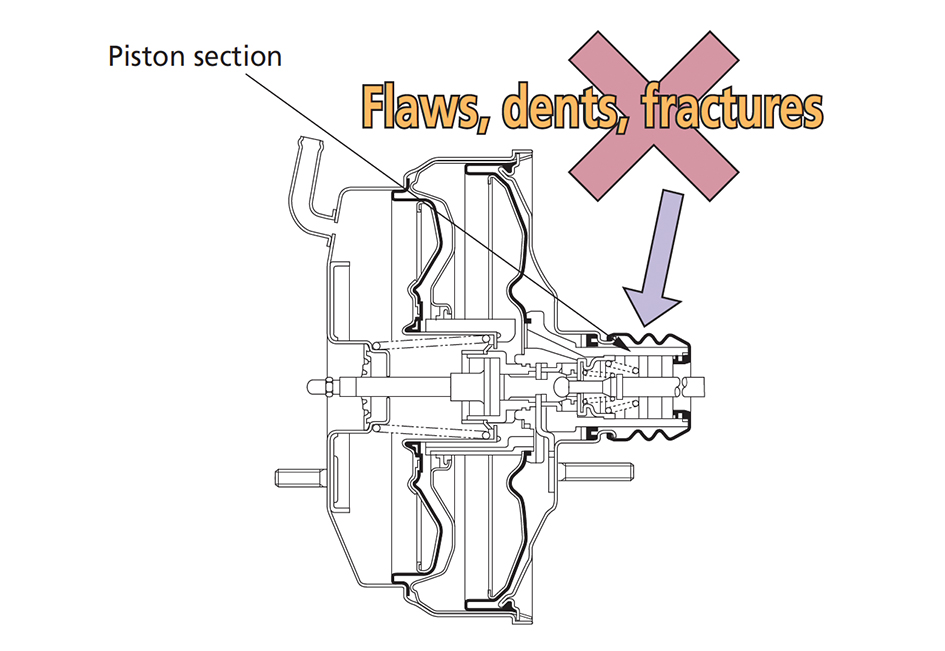

Confirm that the piston section is free of flaws, dents, fractures, etc.

Insufficient pressure or leaks may occur if damaged.

02.

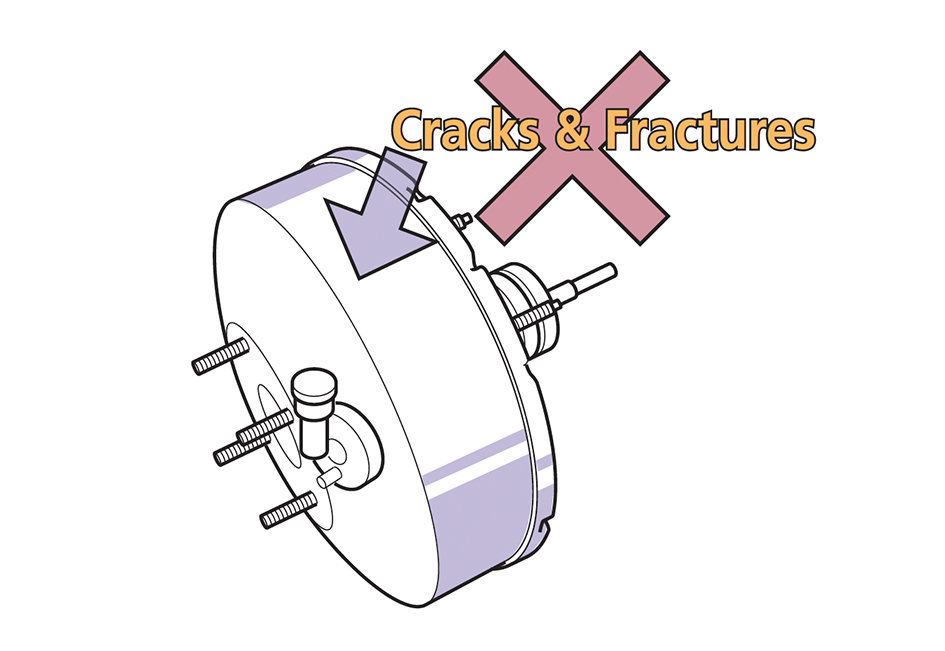

Confirm that the body is free from cracks or fractures.

Insufficient pressure or leaks may occur if damaged.

03.

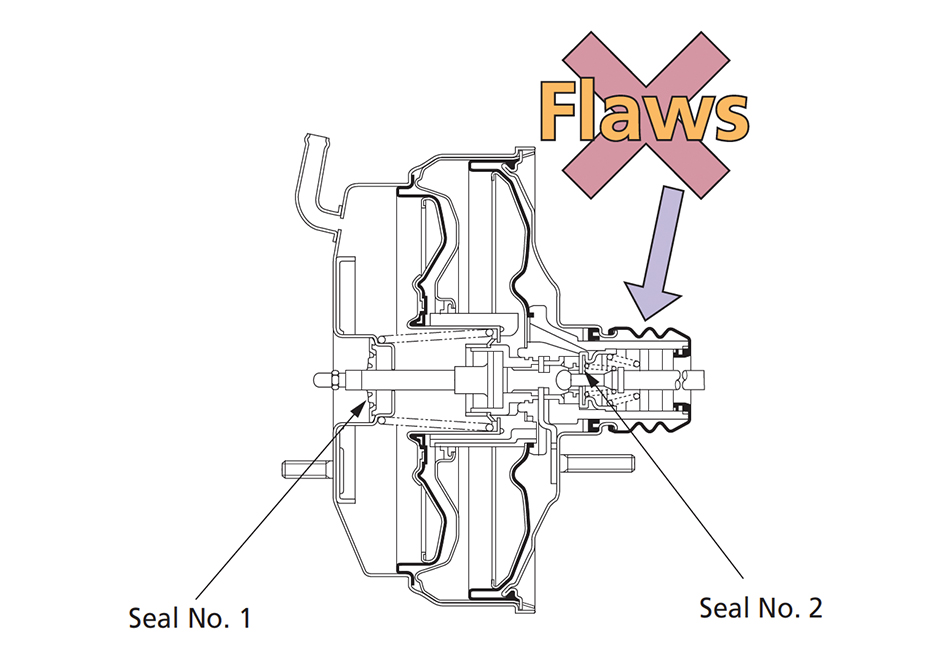

Confirm that Seals No. 1 & 2 are free of flaws.

Insufficient pressure or leaks may occur if damaged.

04.

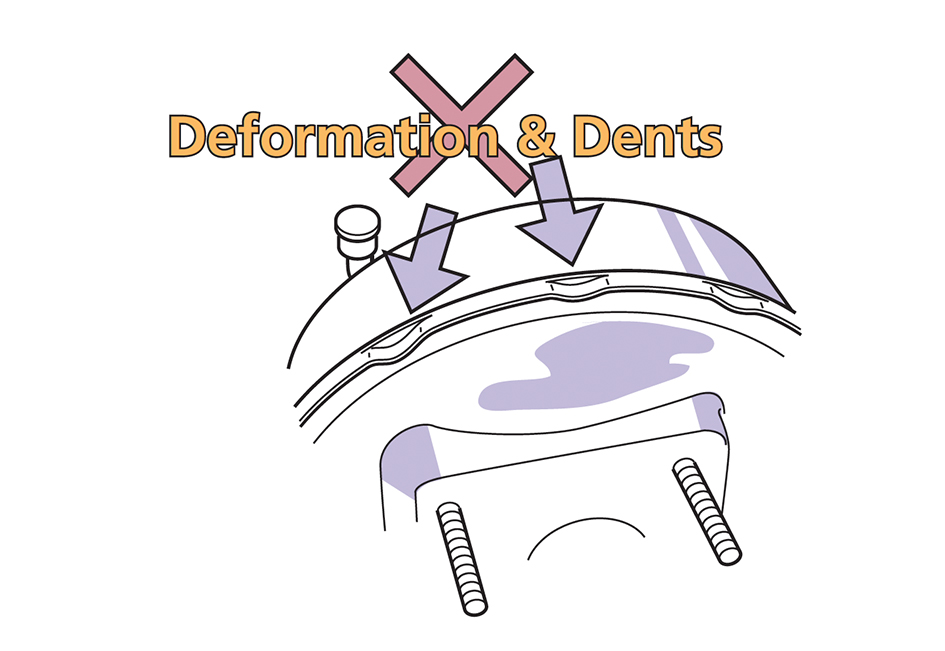

Confirm that the caulked area around the perimeter of the body are not deformed or dented.

Insufficient pressure or leaks may occur if damaged.

05.

Do not hold or lift from the input rod.

Internal parts may be damaged and the brake booster may fail to operate correctly.

06.

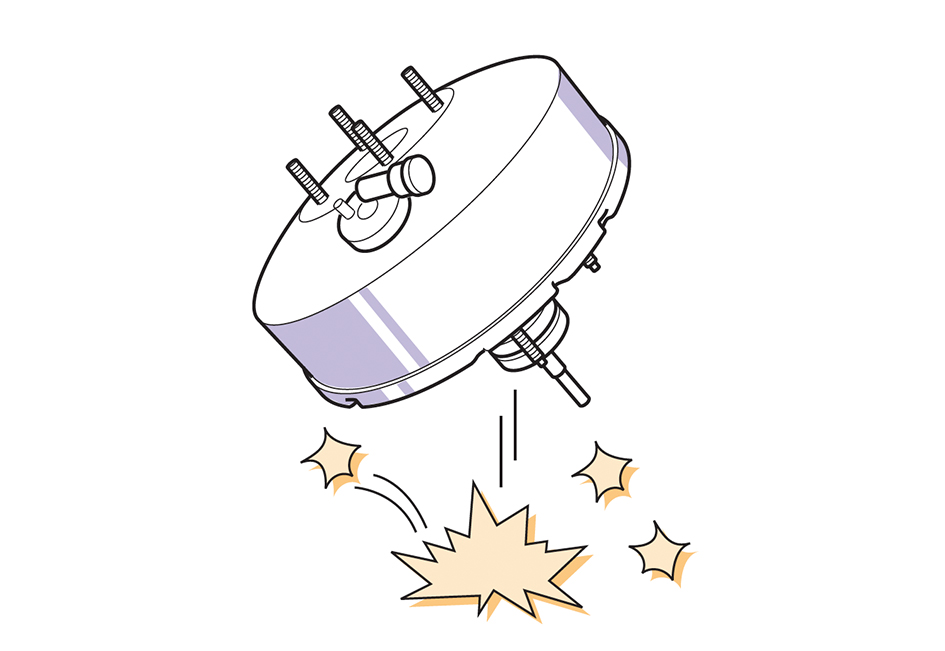

Handle with care. Do not drop or deform. Do not install if damaged.

Brake booster may fail to operate correctly.

07.

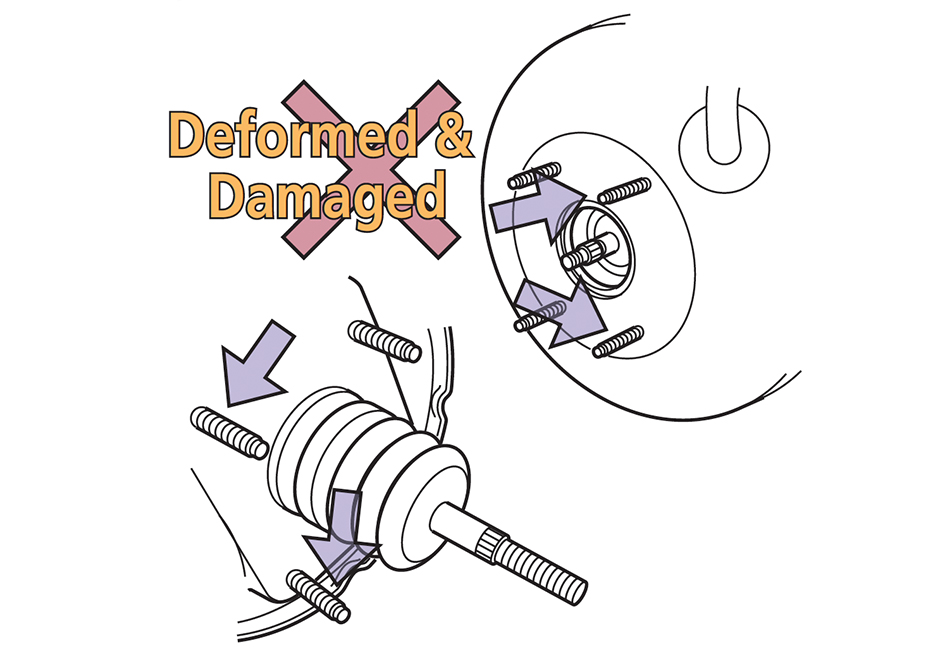

Confirm that bolts are not deformed or damaged.

Brake booster may not mount properly causing failure to operate correctly.

08.

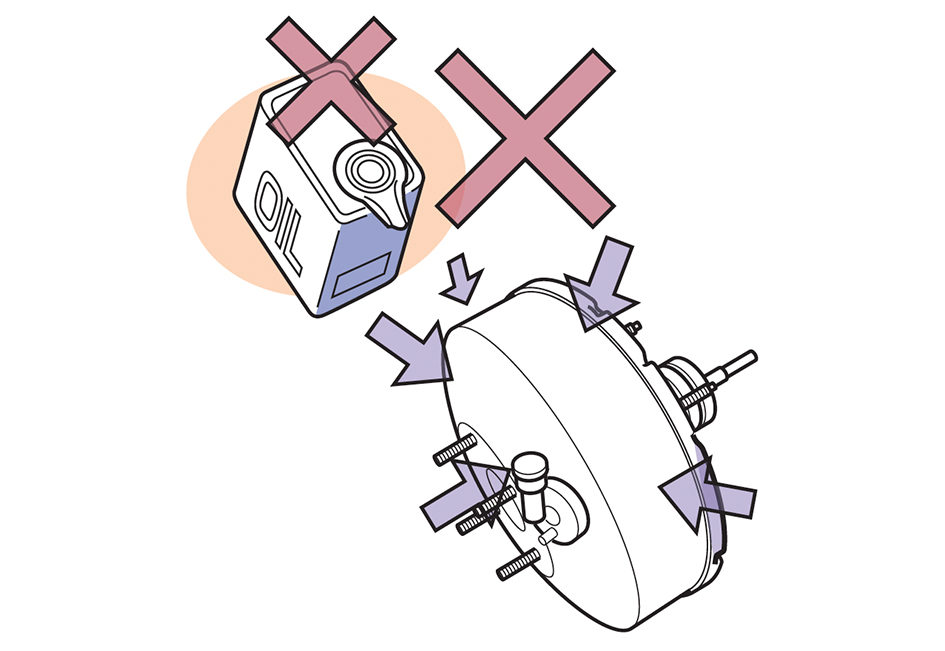

Do not contaminate the brake booster with oil, grease, brake fluid, etc.

Contamination may cause the paint to peel, exposing bare metal to the elements.

09.

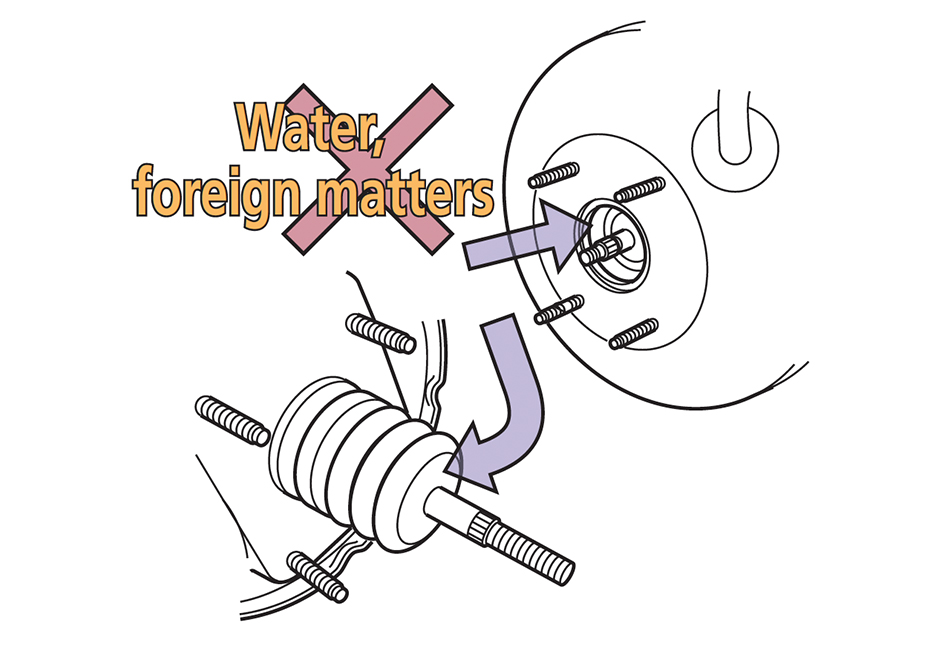

Take care to protect the inside of brake booster from ingress of water or foreign matters.

It could cause rust formation at the inside or damage seals so that the brake booster may fail to function properly.

Caution!

Failure to follow recommended procedures may cause brake failure and injury. Always consult the manufacturer’s vehicle specific service manual for reference.